Tariffs: Manufacturers are Ill-equipped for Raw Material Cost Hikes

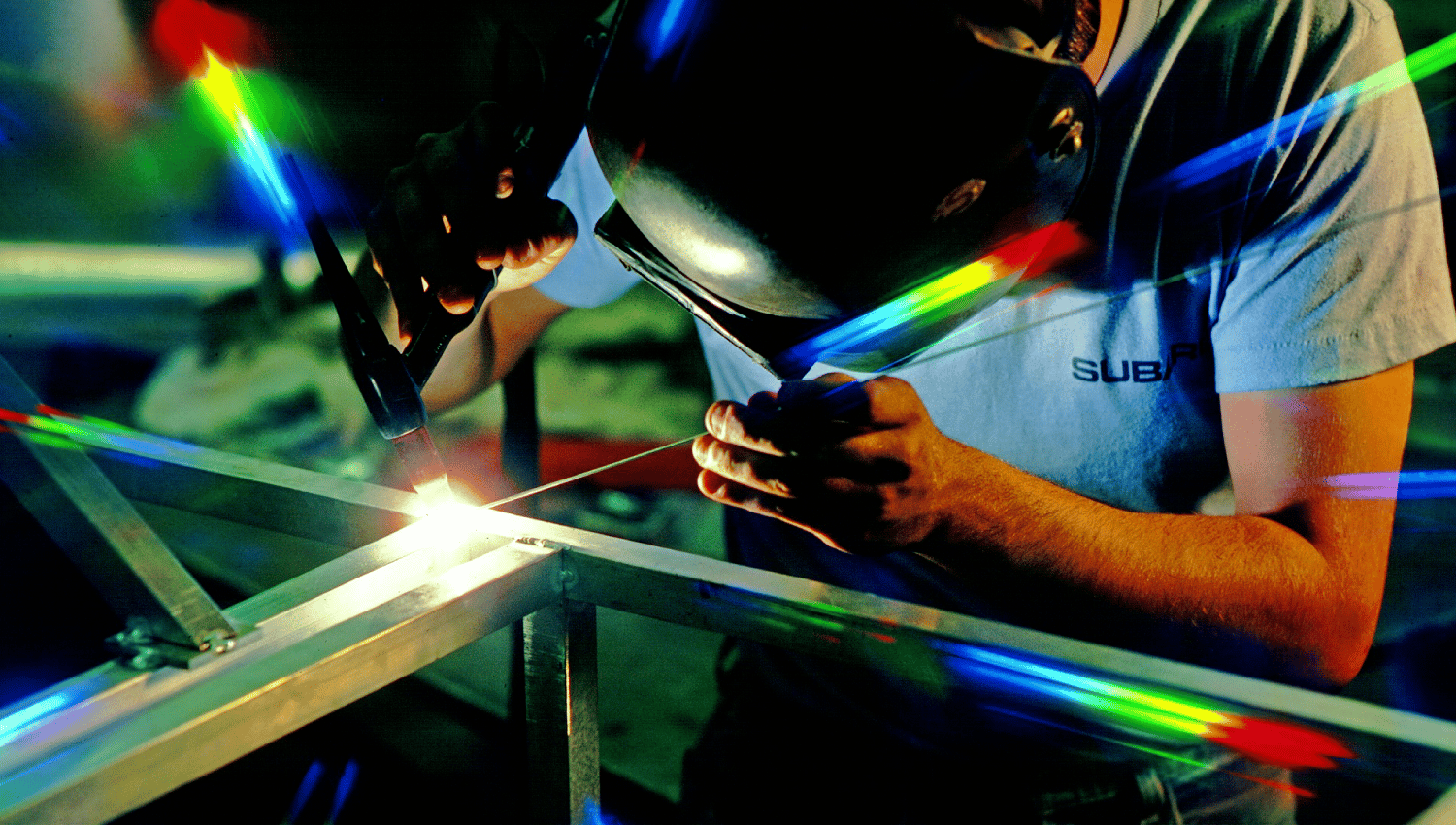

The import tariffs on steel and aluminum, as confirmed by President Trump on May 31, exacerbated worries for B2B manufacturers—and their customers. The implications for employment and the economy are significant, but most manufacturers are also grappling with practical questions, such as: How will this impact my per-unit costs? How can we effectively pass these changes on? How will customers react to an across-the-board price increase? How can we hold the line on margin erosion and do so quickly?

Interestingly, a steep rise in costs may exacerbate existing pricing issues for manufacturers, most of which lack an effective method for variable cost management. For many, standard costs are locked in annually, leaving little leeway for unexpected cost hikes. Regardless of the in-house process, the bottom-line impact of slow, overly-simplistic cost changes is significant. Let’s explore how being ill-equipped to manage cost volatility manifests on the balance sheet.

The bottom-line impact of slow, simplistic response to cost changes

A recently-conducted analysis of more than one-billion global B2B transactions revealed that when manufacturers lack the ability to quickly, granularly and effectively update prices in response to volatile cost swings, they fail to capture the full value for their products.

For the global manufacturing dataset analyzed, the aggregate impact of not addressing cost changes quickly and accurately ranges from 0.6 to 8.7 percent in lost profits. For a $300 million manufacturer, this equates to $1.8 million to $26.1 million in uncaptured annual profit. The good news is that a healthy portion of this can be captured with optimized, market-aligned pricing. Let’s explore.

Status quo of pricing in B2B

We don’t have a crystal ball to know precisely when, if, and by how much impending tariffs will impact raw material costs for manufacturers. We do know, however, that many companies are lacking an effective game plan to deal with cost hikes of this magnitude when they happen.

As the above research suggests, most B2B manufacturers don’t have an effective way to manage how much of a cost change they pass on in the form of price. While manual updates can be effective on a small scale, when you are dealing with a massive customer base and product catalog, across-the-board price hikes often backfire. When volatile cost swings hit, manufacturers need a method to deliver market-aligned prices that effectively mitigate cost without losing a significant amount of business. This is especially relevant if we’re entering an unprecedented trade war era where tit-for-tat policy decisions have the potential for frequent, short-notice impacts on raw materials and finished goods alike.

Unfortunately, the urgency to make a change quickly and a lack of familiarity with the increasing capabilities of pricing teams to make variable, targeted, sticky increases means that many executives still demand flat increases. In many cases, the broad-brush approach increases the risk of compromising both business and profit.

Further, these across-the-board price increases run the risk of over-charging some customers while under-charging others. We see time and again that broad-brush price changes only ever achieve a portion of the stated goal. For instance, if you have to announce a 5 percent action and hope that 2 percent sticks, you’re not taking advantage of segmentation fundamentals or the demand curves inherent in your customer’s populations as you respond to cost changes.

Use AI to predict the impact of price changes

While you can’t predict the future, artificial intelligence (AI) can help you make accurate forecasts on the probable business impacts under a set of assumptions. Current best practice is to set unique cost pass-through strategies at the product family level in the pricing segmentation hierarchy. In this way, automated price response adjustments are consistent with your knowledge of the varying ability of different categories to digest these changes. This means that lean pricing teams won’t need to make manual calculations with every tariff-driven cost change.

With AI-driven price optimization, you can explore alternative scenarios for raw material cost changes by predictively exploring the alternate outcomes of a five, 10 or 20 percent cost increase. AI-driven price optimization lets you apply these “what-if” scenarios to customer micro-segments to visualize how price changes will impact profit and revenue before the new prices are put in-market. With this knowledge, companies can have multiple battle plans at the ready when the present cost uncertainty turns into a true cost change.

Get better and faster results

For manufacturers that have a lot of complexity in the types of customers they serve, an across-the-board price increase usually doesn’t suffice. They should, instead, opt for a cost-adjustment strategy that accounts for each customer’s price sensitivity, their existing contracts, regional competitive factors, and the types of products they are buying from one order to the next.

While we can’t predict when the next cost crisis will hit, we can say with certainty that they will continue to happen. Instead of bracing for impact, consider proactive discussions with your CFO or CEO. Now is the time to consider how a more nuanced approach to cost-pass-through can generate a better and faster result than a flat increase.